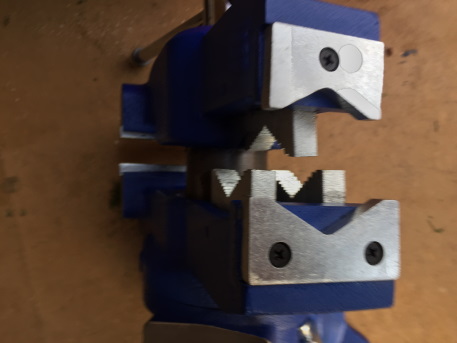

A vise (sometimes spelled vice) is used to hold objects in place so that they may be worked on. It’s pretty straight forward, you don’t want a work piece wiggling around while you are trying to cut it, glue it, sand it, file it, drill it, or otherwise modify it. You also don’t want to have to hold that work piece still with your hand. A good vise will keep a work piece completely immobilize while keeping both of your hands free.

If you are looking to purchase a vise, check out my guide.

While I already gave a preview of some of the things a vise can be used for in the paragraph above, I will try to get more specific on how a vise may be used in various industries.

What is a vise used for in metalworking?

As someone with a background in blacksmithing, I mostly commonly use my vise for cutting or filing stock. Both cutting and filing require that I have a heavy duty vise that can withstand some pressure.

What is a vise used for in woodworking?

Much like with metalworking, a vise is very useful for holding wood stock still while cutting or sanding. A vise is also great for gluing wood pieces together…more on that below!

Gluing

A vise is a great tool to use when gluing separate pieces of stock together, particularly in woodworking. You can apply your glue, clamp the two pieces together with your vise, and then go do laundry while you wait for the glue to dry. Many woodworkers will also utilize hand clamps or c clamps along with their vise to make sure pressure is applied evenly across the stock while gluing. This helps ensure a strong bond that will last a long time.

Drilling

A vise can be used for drilling operations as well. There are specialty vises made just for drilling that work well for these types of operations. These specialized vises will often have a tilting mechanism that allows for a wider variety of drill angles when using a vertical drill. A vice or clamp of some sort is vital when drilling harder materials, as they can reduce the chance of an item “spinning out” of control as the drill turns into the piece. Drill Vises also tend to be very heavy and very dense.

Adjusting And Screwing

Have you ever had a lid or cap that was on so tight your fingers slipped while trying to take it off? A vise is a great way to solve these types of problems.

Automobile Work And General Machining

A good vise also has many uses in machining and automobile work, but this is outside my circle of competence. I mostly use it for blacksmithing and bladesmithing projects.

A Thing Not To Do: Use Your Vise As A Press

It may be temping to use your vise as a press, but you should avoid this temptation. Even a simple arbor press has a sturdier design than a vise for pressing. A vise uses a lead screw to move the movable jaw forwards and back. This is great for quick clamping, but it will break and wear out very quickly if you use it to apply great pressures.

A small pressing tool, like a tabletop arbor press, will use a rack and pinion setup to apply force rather than a a lead screw. And the heavier duty presses will use even sturdier mechanisms.

In short, a vise is not a press, don’t use your vise as a press if you value its longevity!