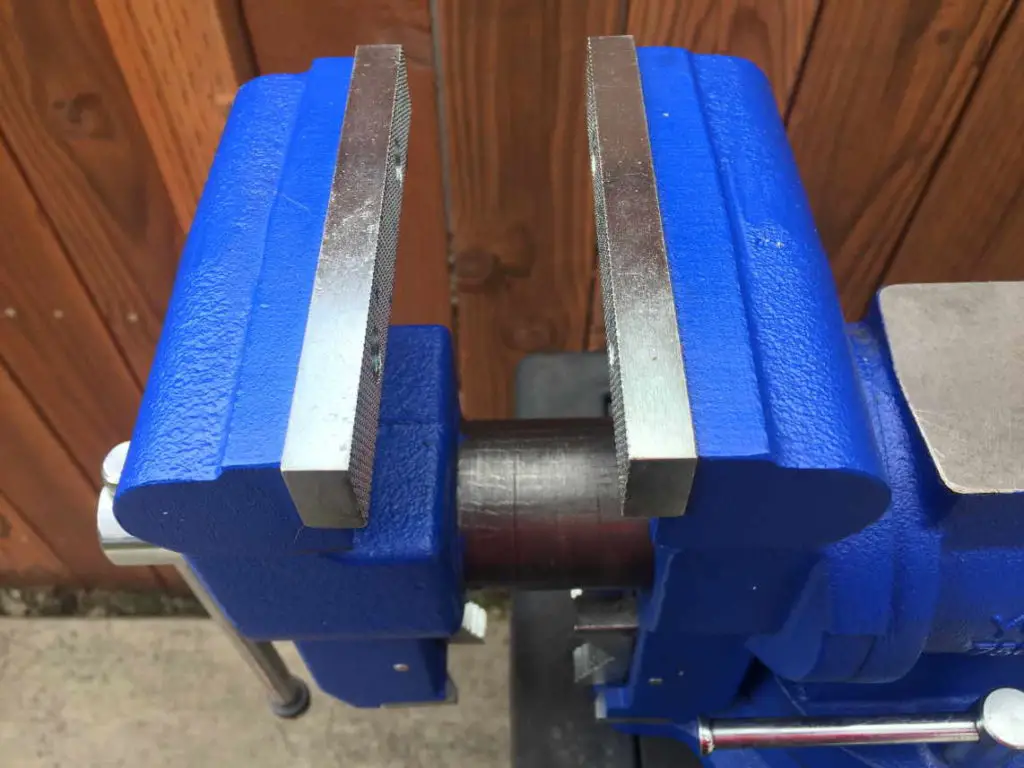

A vise has two parallel jaws that come together to clamp an object in place.

There is a stationary jaw, which does not move and helps provide stability.

There is a dynamic jaw which is moved away from or towards the stationary jaw along the length of a lead screw. The lead screw is turned by way of a handle at the end of the screw. Many lead screws are hidden inside a case to prevent debris from falling into the screw and ruining it’s performance.

The leverage from the handle and the motion of the screw allows you to clamp things together with considerable force, although you should not confuse your vise with a press, which has a more sturdy mechanism* than a lead screw.

*A small arbor press will use a rack and pinion rather than a lead screw. Larger presses will use even more sophisticated methods. Either way, a lead screw is not designed to apply a great deal of pressure.

And that’s pretty much it. If you are looking to buy a vise, check out my article on which vise to buy. If you are looking for more details on how they work, read on.

In order to do it’s clamping function properly, a vise must be attached to the table in some manner.

Stationary vises are usually bolted to your workstation and provide additional stability in exchange for not being able to move.

Movable vises will tend to have a clamp on the underside of them – usually a c clamp – that allows them to be moved on the work site. Movable vises tend to not be as sturdy but are sufficient for many tasks.

More advance vises may have the option to rotate the vise head, or may even have multiple sets of jaws on a single vise. For example: some vises allow you to have both a pipe vise and a normal vise on one machine.

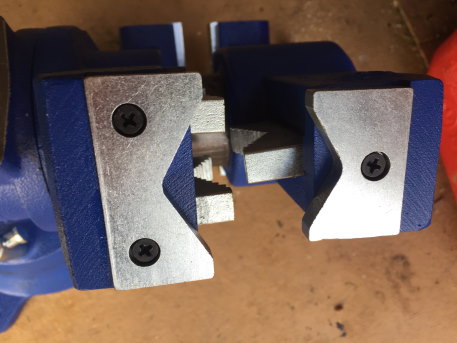

Many vises also have easy to remove jaws, allowing you to put in jaws of softer or harder material depending on the project you have in mind. You can also place a cover that slips on over the outside of the jaw. Some jaws are smoother to avoid leaving an imprint, and some jaws have ridges to improve grip.

Some vises are made specifically for drilling vertical holes, and will have a tilt function allowing you drill holes at several different angles.

Regardless of all the different variations that are possible, all vises do essentially the same thing: They move a set of parallel jaws towards each other to create a clamping mechanism.

And there you have it. A vise is a simple tool, although it’s incredibly useful for so many different crafts!