While screws and presses – the fundamental building blocks of a vise – have existed for thousands of years, the vise -sometimes spelled vice – as we think of it today did not come about until the middle ages. Before more modern designs were put into place, craftsman had to use a cumbersome system of hammers and wedges to hold an object in place.

The era of the wooden vise

This practice changed in 1750 with the invention of the parallel vise. In this design, one of the vise jaws could move horizontally along the length of wooden screw.

But vises made out of wood were not very durable, and were subject to all the wear and tear you would expect from a wooden material used in an industrial capacity.

Which why both consumers and manufacturers of historical vises were on the lookout for a better material.

The era of the cast iron vise

In 1830 England, that better material came when the first cast iron vise was produced. These cast iron vises were much stronger than the wooden ones that came before, but they were inferior to the vises we have today.

These cast iron vises had a high carbon content making them brittle. They also had cavities created by air bubbles that would form from the inferior casting techniques of the time.

The difference between a historical vise and a modern one – why the modern vise is better

A modern vise is either made from casted ductile iron (which has superior material qualities over the old cast iron vises due to the nodular graphite inclusions in its micro structure), or is forged.

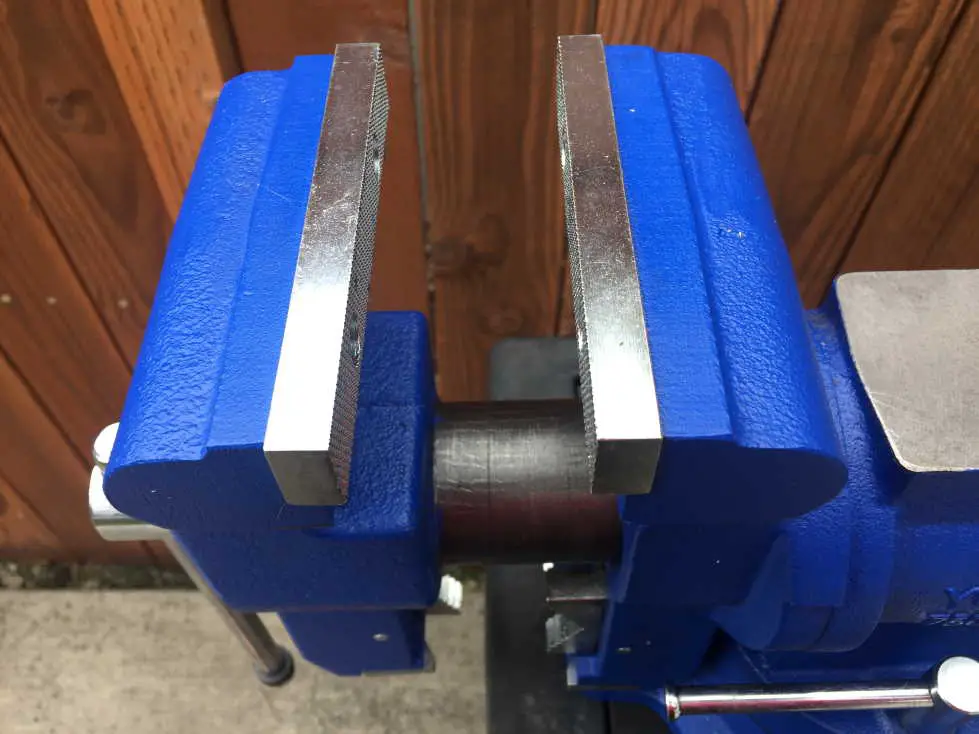

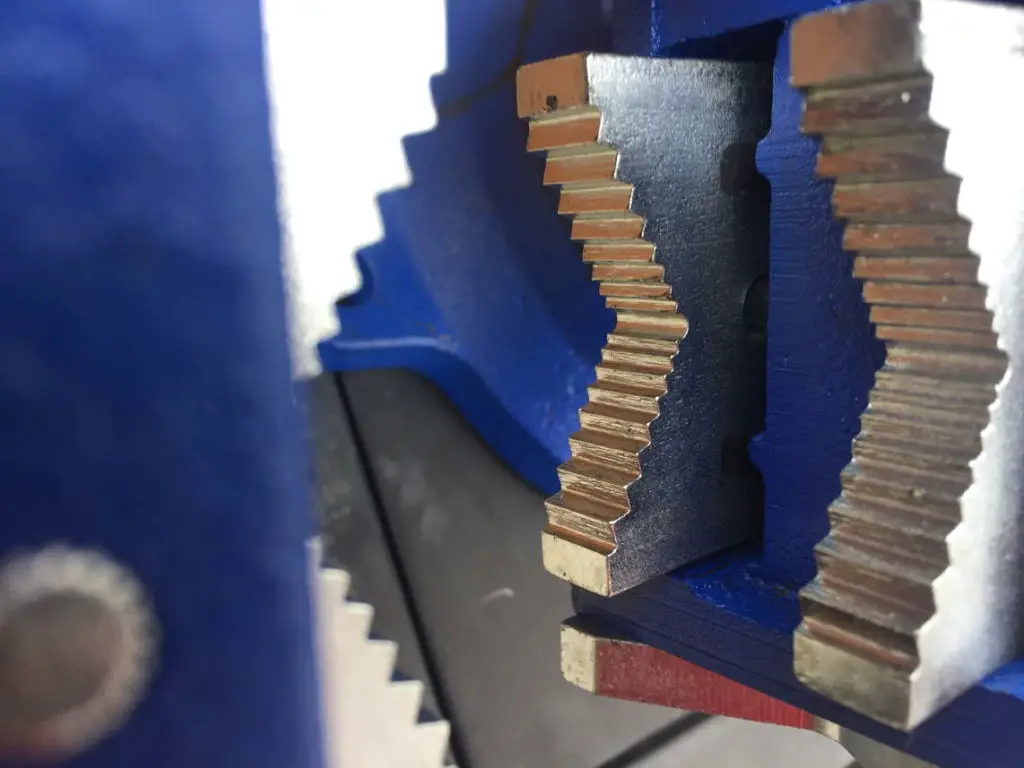

In addition to being made of superior materials, a modern vise may also have additional features which were not present in historical vises. One such feature is the ability to rotate the vise head in a circle – allowing you more flexibility in your vise setup. Another feature may be that the vise has multiple jaws, allowing it to have a typical vise jaw along with a more specialized set of jaws such a pipe jaw.

Modern vises may also come with a variety of changeable jaw covers and teeth, allowing for a softer or more aggressive clamping surface as the project may require.

Finally, a modern vise may come in either a fixed variety, or a movable variety. A fix vise is bolted into a table or work bench. This makes it sturdier at the expense of it’s mobility. A movable vise will often come with a clamp that allows you to attach the vise to different surface through the course of your work. Movable vises tend to be smaller and less sturdy, but are can be more convenient to use, especially on mobile job sites.

Despite all the bells and whistles you can find on a modern vise, the fundamental technology is the same as the ones made 250 years ago. You have two parrallel blocks that are brought together via a lead screw creating clamping pressure. That’s it!

If you are interested in acquiring a vise of your own, check out my guide to purchasing a bench vise.