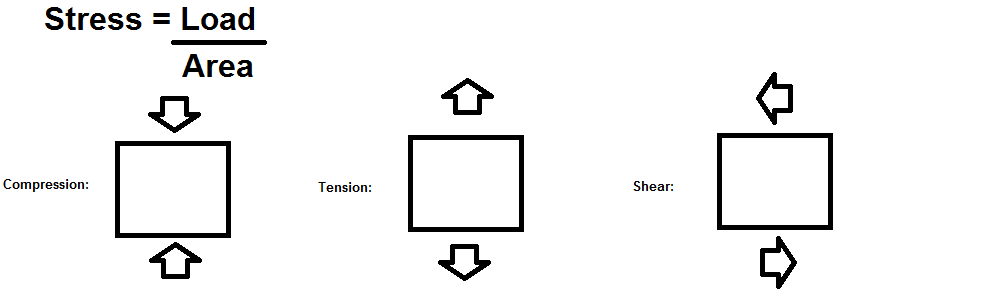

Put most simply, Stress = Load/Area. Stress tells us with how much force the atoms at a point within a solid are being pushed together or pulled apart by the load. There are primarily three different ways in which a load may be applied: tension, compression, and shear. Tension is when the material is pulled apart. Compression is when the material is being smooshed into itself – that is, it’s length decreases. Finally, shear is when the faces of a material are sliding opposite of one another. To understand shear, imagine a cube: apply a leftward load on the top face and a rightward force on the bottom face. In engineering disciplines, many forces are torsional rather than pure shear.

Strain = Extension under load/Original length. Another way to think of it is strain is the change in length divided by the original length of the material.

Hopefully this answers the question of what is stress strain. There are some similar questions answered below.

What is Young’s Modulus?

The formula for Young’s Modulus is E=Stress/Strain. It measures the tensile elasticity of an object when stress is applied to it. For most metals that are stressed in tension at relatively low levels, strain and stress are proportional to each other. This general rule is known as Hooke’s law. Deformations in which stress and strain are proportional may also be called elastic deformations. If you were to graph this relationship, it would come out linear. To improve intuition, this modulus may be thought of as stiffness, or a materials resistance to to elastic deformation. The smaller the modulus, the less stiff the material is, which leads to a greater elastic strain for a given stress.

How is Tension Measured?

Firstly, the material to be tested is mounted by its ends into the holding grips of the testing apparatus. The tensile testing machine then begins to slowly pull apart the material by providing a steadily increasing tensile force that is applied uniaxially along the long axis of the material. The rate of increasing force should be constant. The stress is measured by an instrument called an extensometer. Extensometers are used to measure the deformation of a material under stress.Here below is a video showing how it’s done:

How is compression measured?

Compression stress-strain tests are similar to tensile tests. However, there are some differences. By convention, compression forces are taken to be negative, which of course yields negative stress. In general, tensile tests are more common than compression tests as they are easier to run. In addition, the information gathered from compression tests tends to be similar to the information gathered from tensile tests.

Sources for this article include:

Fundamentals of Materials Science and Engineering by William D. Callister, Jr.

Structures Or Why Things Don’t Fall Down by J.E. Gordon