A vise is not a complicated tool. You can get by without knowing all the various dimensions and measurements that manufacturers provide when selling a vise.

Bolt a vise to a table, put something between the vise jaws, and turn the handle attached to the lead screw. VIOLA, your vise is working as intended.

But while you don’t NEED to know all the various dimensions and subtle ways in which one model of vise can differ from another, it can be helpful to do so.

A vise can be a big investment for the home hobbyist – depending on your income. Not only can it be a big investment, but a vise is a tool that gets used almost daily. It’s a bread and butter tool. Almost every shop will have one.

So you have a tool that can cost hundreds of dollars, gets used daily, and can be a great source of frustration if it’s the wrong size for either your workbench or the items you will be gripping.

With that in mind, it seems worthwhile to learn a few key terms and dimensions doesn’t it? Don’t worry, this isn’t school, you won’t be graded. And really, there are only THREE measurements that I think are really important, the rest are an added bonus.

Let’s get down to it.

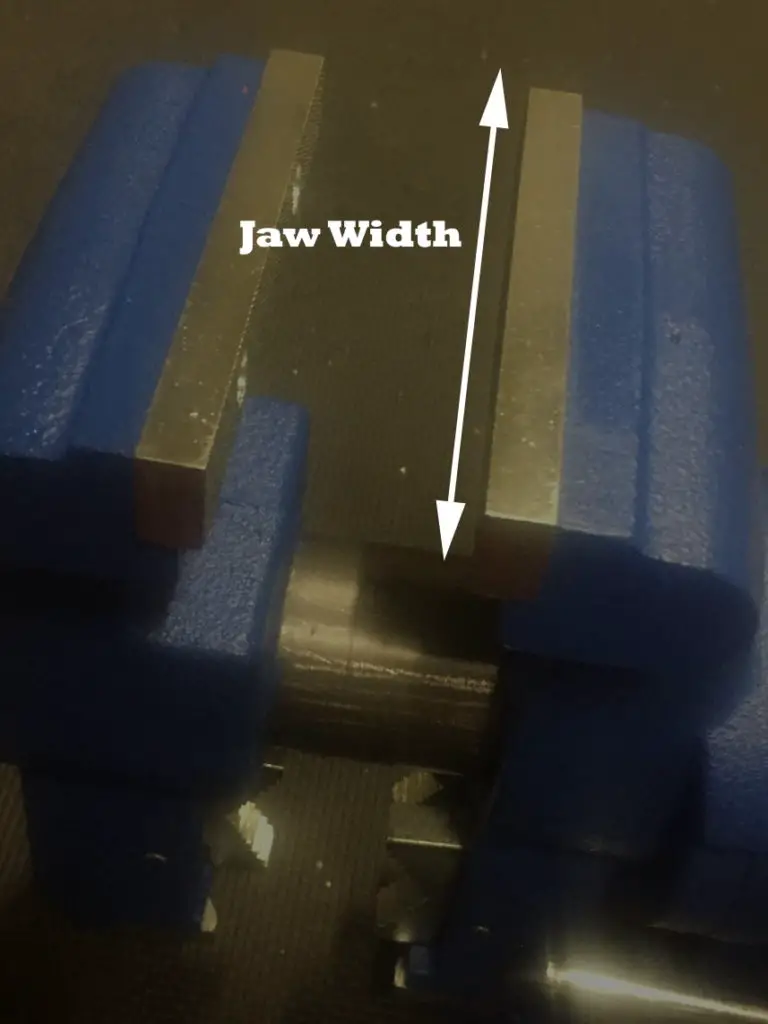

What is the vise jaw width measurement?

What is the vise jaw width measurement – what is the definition? The vise jaw width tells you how how long the vise jaws are on the horizontal axis. It is measured from the top corner of one jaw along the horizontal axis to the other end of the same jaw. Verbal definitions are always a mouthful, the picture above is worth a thousand words.

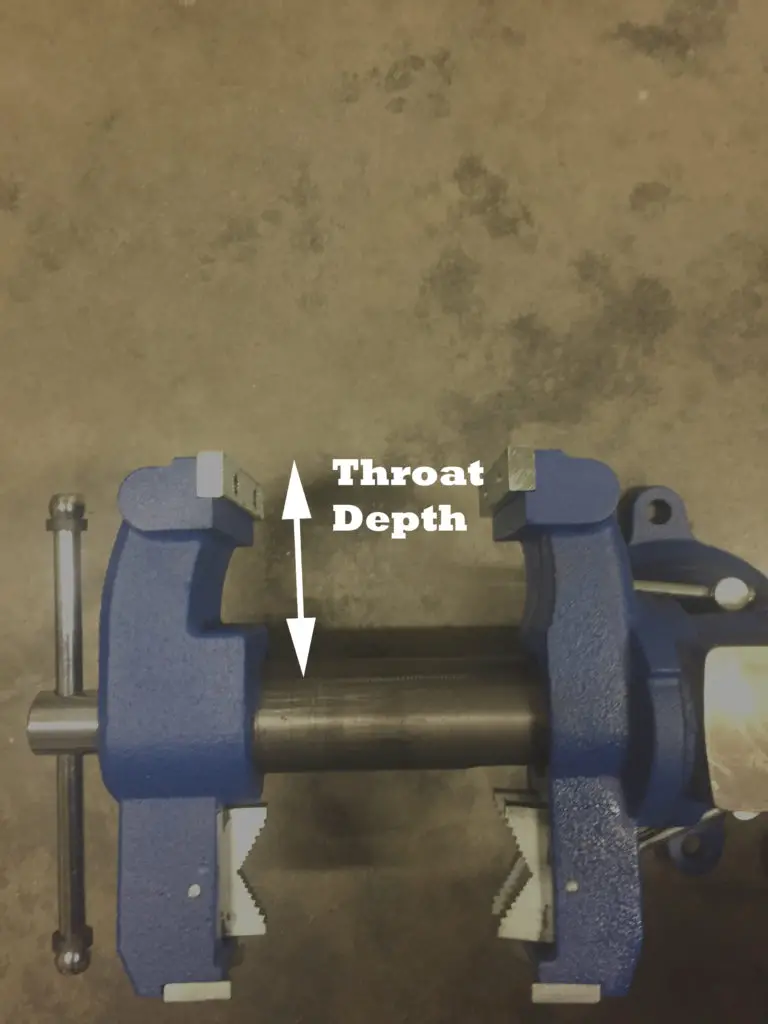

What is the vise throat depth measurement?

What is the vise throat depth measurement – what is the definition? The vise throat depth tells you the vertical capacity of the vise. It tells you the vise depth. It is measured by measuring the distance between the top of the vise jaw down to the lead screw or lead screw case. It is arguably one of the most important vise measurements, as it can be very difficult to fit items that are significantly larger than the throat depth into a vise.

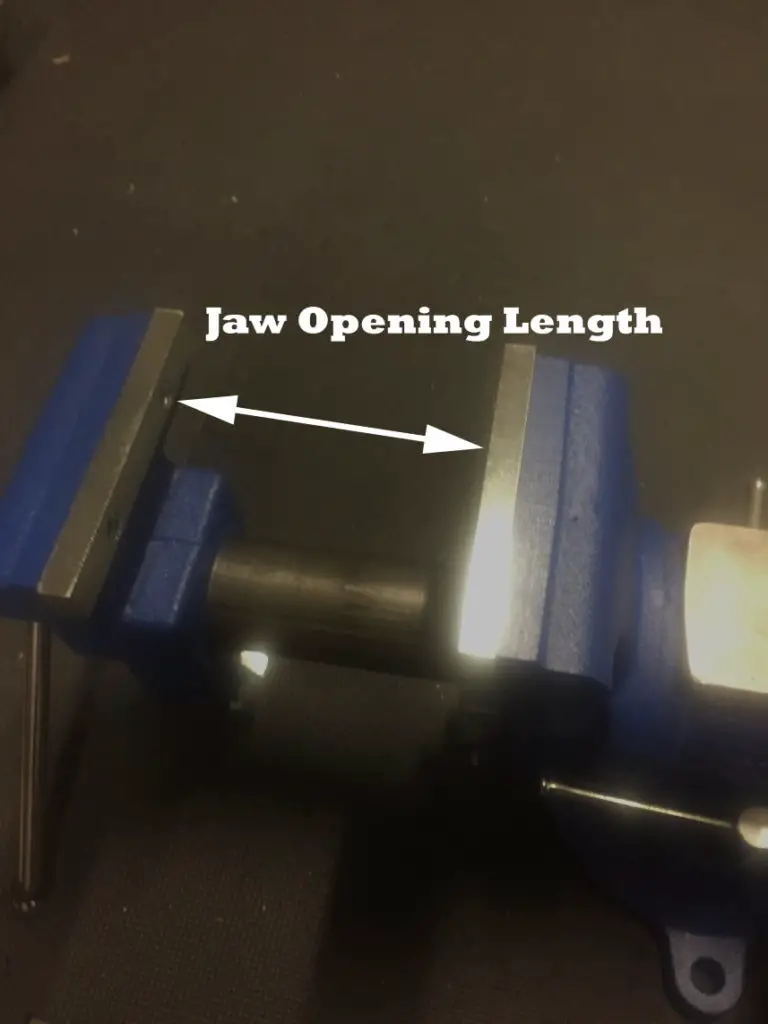

What is the vise jaw opening measurement?

What is the jaw opening measurement – what is the definition? The vise jaw opening measures how wide you can open your vise jaws. Put another way: it measures how far apart the two jaws of your vise can go.It is measured by taking the distance between the two vise jaws when the lead screws has been turned as far as it will go.

These are the “big 3” measurements. They are the most important in my humble opinion, as the all directly dictate how big of a piece of stock you can put in your vise.

There are others however, I will go over them below.

What is the vise handle length measurement?

It’s exactly what it sounds like. I didn’t include a picture for this one. It is however just as important , particularly if you are not placing your vise on the corner of your workbench. You don’t want a long handle on a short vise if you are placing the vise in the middle of your table, as you will bang the handle into the table every time you turn the screw. This problem can be easily avoided by putting your vise on the corner of your work station, as the handle will hang freely over the edge.

What is the weight of a vise? Why is it important?

Ok, so no one is searching for this question, so I won’t belittle you by explaining what weight is. But it’s important to consider the weight of a vise, as heavier vises will require a heavier work station to bolt it into. You don’t want to place a heavy vise on a flimsy table or on a rolling table (with casters) that is too narrow or too light to hold the vise up. A vise falling from waist height in a table length arc can make quite a mess! Heavier vises can also generally handle heavier workloads and suffer more abuse – assuming they are well built, a vise is like any other machine, and is only as strong as its weakest point!

Clamp Opening

While heavy duty vises are usually bolted to a table, smaller varieties will often have a clamp on the underside of the vise that allows you to quickly attach it to working surfaces. The clamp opening just measures how wide this clamp opens. My vice doesn’t have a clamp attached to it, so I just posted a picture of a C clamp below as this is generally the shape vise clamps come in.

And that’s it! You are now and expert on vise dimensions. If you are looking to acquire a vise of your own, make sure to check out my guide to buying a vise.