Whether it’s punching a hole for the eye of an axe, a hammer, or some other handheld tool, the trusty blacksmith punch is a great low tech solution for making holes in a piece of stock. There is no need for expensive machining equipment when you have a punch lying around.

Today I will go over some basic information about punches. What are blacksmithing punches? what is the best steel to use when making a punch? What different types of blacksmith punches are available? How do you use a blacksmith punch? Which blacksmithing punches should a beginner buy?

Before we get to all that, it may be useful to go over some more general information, so that you have a broad understanding of these tools.

What Are Blacksmith Punches Used For?

It’s pretty straightforward to be honest.

- Punching Holes

- A hole for fasteners

- A hole for the eye of an axe or some other tool

- Decorative Stamp

Steel Selection For Blacksmith Punches

While I sometimes like to pretend I’m the master of all blacksmithing knowledge(joke), I have always been a bit weak when it comes to alloy knowledge and metallurgy. For most projects this isn’t a big deal – as mild steel works for most projects- but I think it matters a fair bit with punches as punches have to endure quite a bit of heat/kinetic abuse.

So to overcome this deficiency, I’m going to try and compile recommendations from other well known blacksmiths on what is the best type of steel for a punch.

John over at the excellent Black Bear Forge recommends the following alloys:

4140

4140 is a steel that is alloyed with chromium and molybdenum, as such, it is sometimes referred to as chromoly steel. This steel has a good strength to weight ratio and is harder and stronger than standard steel, making it great for our purposes of creating a blacksmith punch.

Interesting to note, 4140 has significantly less chromium than most stainless steels, hence why we don’t see the same corrosion resistance in 4140 that we see in stainless steel.

According to Metal Super Markets, AISI 4140 steel is composed of .8-1.1% chromium and .75-1% molybdenum.

5160

5160 is another great steel for making blacksmith punches. 5160 has a tensile strength of about

105000psi (source ) vs 95000psi () for the 4140 examined earlier, this make 5170 slightly stronger than 4140.

According to the site linked above, it has about the same hardness as 4140.

S7

S7 is a steel designed with shock-resistance in mind. It does this at the expense of hardness(source). You made be concerned with the drop in hardness compared to the other two steels we discussed, but don’t be. Hardness isn’t as important with punches as it is with cutting tools that have an edge. S7 is a great steel for blacksmith punches.

Sooo Which One Should I Pick?

Any of the above 3 will work fine. Pick one you have experience with if possible. If they are all foreign to you, pick one based on price or ease of access. Really, unless you are doing some highly optimized industrial process, all will work well

Types Of Blacksmith Punches

All blacksmith punches serve a similar purpose in that they are used to create a hole in a piece of stock. I’m going to include drifts and chisels in this list as well as they are used for this purpose too.

Because there are so many custom made punches out there, it’s not possible for me to list every type of punch/chisel/drift in existence. I will go over some of the more popular ones below.

- Blacksmith Drift

- Slitting Chisel

- Slot Punch

- Square Punch

- Ball Punch

- Eye Punch

- Decorative Punches

Blacksmith Drift

While punches are used to create holes by shearing out unwanted material, drifts are used to further shape the inside of already created holes. Drifts are often used in conjunction with slitting chisels or slot punches.

Blacksmith Slitting Chisel

Slitting is using a chisel to cut a hole in the middle of a piece of stock. Slitting is often used in conjunction with drifts to further shape the hole provided by the slitting chisel. If you ever hear the phrase “slit and drift”, this is the process it’s referring to.

Blacksmith Slot Punch

There is a fair bit of overlap between a slot punch and and a slitting chisel. Colloquially the terms often get used in haphazard ways, so I’m not honestly sure if there is a standardized difference between the two. In my mind, a slot punch is somewhere between a chisel and a normal punch…but this may not be correct.

For a more authoritative source, check out Mark Aspery’s short video on the matter:Source

Blacksmith Square Punch

As the name would suggest, square punches are used for punching out square holes.

Blacksmith Ball Punch

These punches are used to make round dimples or holes in stock.

Blacksmith Eye Punch

Eye punches are used for making inverted dimples (small bumps) in the surface of a stock.

Blacksmith Decorative Punches

This is kind of a catch all category. Decorative punches are specially made to repeatedly and reliably punch a certain shape such as a company logo or a complex shape that would be difficult to engrave by hand.

How to Use Blacksmith Punches

Steps:

- Clamp down your stock that will be punched. Don’t clamp it down over the hardy or pritchel hole, as this will cause ugly bulges and deformations in what would otherwise be a nice round hole.

- Before you heat up a stock, punch a small indent that will serve as your guide once your stock is heated.

- Drive the punch through the material until there is just a sliver of stock left. Make sure to cool your punch frequently in water, especially on deep cuts. DO NOT let your punch get to a glowing cherry red. If your punch does get too hot, let it air cool before you cool it in water –

A dusty anvil with two hardy tools lying on top. Image source you don’t want it to crack. Your stock will heat up your chisel/punch, in this heated state, your chisel/punch is much more likely to dull and deform.

- When you have just a little piece of material left, flip the piece over and place it over the hardy hole, find where your previous punching efforts have left an indent, and shear through the hole from the other side.

- If you are doing multiple holes, you may need to cool your punch after each use.

Use The Cooling Stock To Your Advantage

Some people find that the final process of knocking the slug out is easier as the piece of stock cools. This is because it makes it easier for the punch to shear through your stock. In addition, it can be easier to see where you hammered on the other side.

To be clear, when I say “cool”, I mean the stock is glowing a dull cherry red. You don’t want it too cold.

Hot Chisels and Punches Vs. Cold Chisels and Punches

Hot chisels as the name would suggest are used on heated pieces of steel. These hot chisels/punches tend to have a slightly sharper cutting angle, making the cutting process easier. They will also have a longer handle, as this keeps the craftsman’s hands away from the hot steel.

Cold chisels and punches on the other hand, tend to have a wider cutting angle. In addition, cold tools are usually heat treated to provide additional strength to the tool. This is why it’s generally not a good idea to use cold tools on hot work, you will lose the temper! These tools are also often used outside the blacksmithing arena.

*For those of you who are new to the craft or have forgotten, tempering increases the strength of a steel at the expense of the hardness.

On hot punches:

I must stress that I’m not an expert on the topic, but I would be wary of using just any old punch tool for sale. As the old saying goes: “If it don’t rust, don’t trust”. This is especially true when using hot punches. I often get accused of being paranoid, but I’d rather be safe than sorry. I would only use plain ol’ steel punches for hot work. I see a lot of affordable punches on amazon, but many of them are coated tools. I don’t think it’s wise using these tools when they are in contact with heated stock.

Best Blacksmith Punches

As with all blacksmithing tools, you can make your own punch if you wish. Most experienced smiths will make custom punches at some point in their career. For advanced projects, it can sometimes be easier to make your own punch rather than try to track down the size/shape/type of punch that you need.

But should everyone make their own punch? Should beginners? I think the answer basically comes down to your motivation level. If the thought of smithing a punch gets you fired up, then hell yea, go make that punch.

But most people get into forging to make cool stuff like unique ornamentation, armour, and weapons. Axes and knives are way cooler than run of the mill blacksmith tools. In addition, if you are a beginner, working with the quality of steel necessary to make a durable punch may be a PITA. Tool steels are harder to work than mild steel, and they are more finicky when it comes to hardening and tempering.

I don’t say this to dissuade people from making their own punches. Far from it! Making your own tools is part of the beauty of blacksmithing. But many blacksmiths are too quick to think they need to make everything from scratch. It can be more fun, and more efficient to just buy high quality tools and get rolling on the good stuff.

I think I will post a tutorial for making your own punch in the future, but for now, let’s go ahead and take a look at some of the best blacksmith punches currently on the market.

Best Blacksmith Punches For Beginners

Best Blacksmith Ball Punch

The first punch on our shopping list comes from Pieh Tools. Pieh Tools was founded in 2003 by United States Air Force veteran Amy Pieh. Growing up, Amy’s parents owned the company centaur forge, so she was surrounded by blacksmiths and farriers from a young age. She brings a lifetime of experience and service and provides good tools for blacksmiths, I highly recommend their wares.

Now that we know a little about our merchant of choice, let’s examine one of the best ball punches for sale. This little beauty is made of ½” round S7 tool steel (good shock resistance). This is an excellent punch that will allow you to quickly starting making beautiful works of art.

Best Blacksmith Eye Punch

This punch is sold by the same company that sold the ball punch previously. The amazon page is a bit sparse, but I’m willing to guess that it’s also ½” S7 steel tool. It is hardy and will be able to hold up to energetic use. Get yours here.

Best Forging Punches For Axe Making

I like using a classic slit and drift.

To punch an eye for an axe, follow these steps:

- Heat the stock to a dull cherry red. Mark the center of your eye at this cooler heat, it’s easier to see your work at this stage. The taller and thinner the stock the more important it is to get your center point in the exact center.

- Heat your stock up to a bright yellow. While you are waiting for this step, decide if it’s better to use a slitting chisel with a drift or whether you should use a slot punch the whole way through. Generally speaking, the slit and drift is better for tall/ thin pieces or pieces where you don’t want the eye to bulge as much.

- Begin punching through the material. Make sure to cool your punch frequently, you don’t want it getting to hot as it will deform. Don’t cool it in water if the punch get too hot, you don’t want to crack it .

- Some people find it easier to punch/chisel in a straight line by rotating the piece 180 degrees after every few blows. This can help you avoid punching at an undesired angle.

Handle Styles For Blacksmith Punches

While I’m sure it’s possible to come up with other combinations, in my mind, there are only two handle types. One has a handle that runs perpendicular to the punch, this keeps your hand far away from both the heat and the hammer. The other handle type is just an extension to the punch.

Alternatives To Punches

Odds are that you are reading this site because you are interested in traditional blacksmithing techniques, that’s great! But it is worthwhile mentioning other techniques as well. Sometimes when you are crunched

for time, it really is easier to just use a drill press. Purists will scoff at this, and that’s fine. But there is no need to handicap yourself if you don’t want to, it’s OK to use modern machinery as well.

For sheet metal it’s also important to remember that you can use a variety of punches such as this hand punch. or this electrical punch.

Conclusion

The need to punch holes is a common one in metal working. You may need to punch holes to fasten two distinct pieces of stock together, or maybe you need to punch out the eye of an axe; either way, knowing the classic blacksmith techniques will allow you to be a more versatile metal worker, and will allow you to tackle anything that comes through your workshop. Stay safe yall, have fun, and happy smithing!

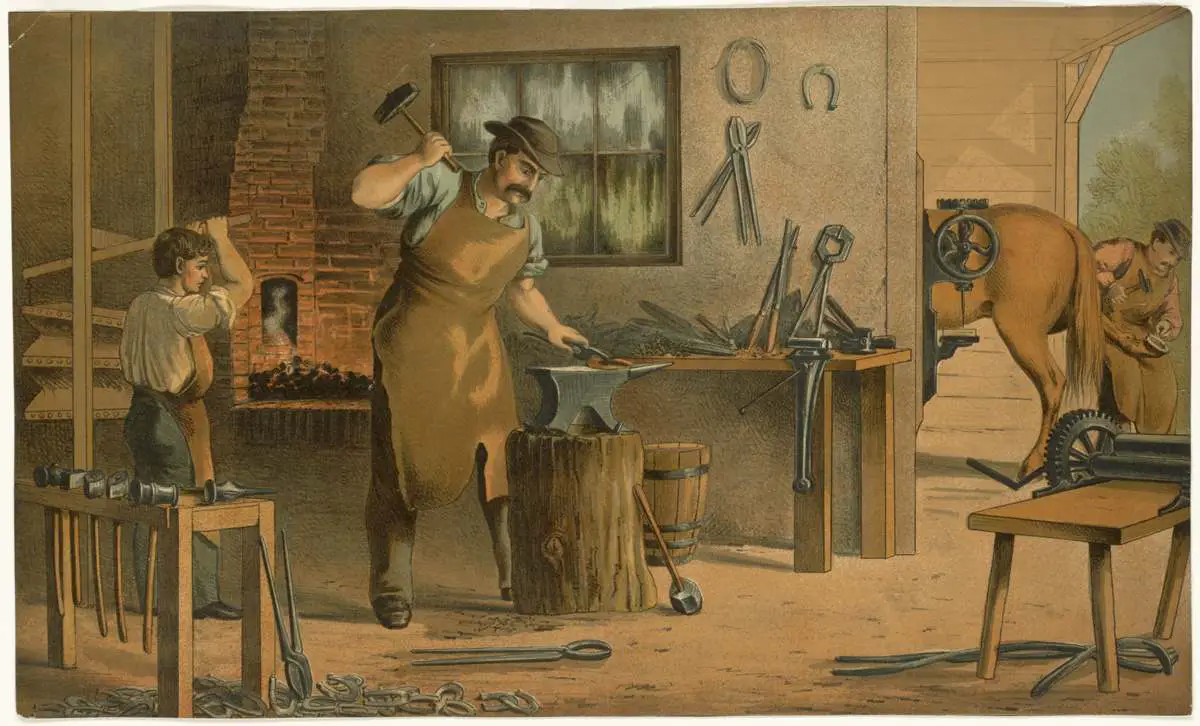

post title image source – Boston Public Library