Vises (sometimes spelled vices) are available in portable versions, and permanent or fixed versions.

Portable Vises

Portable vises as the name suggests are movable. This is great for job sites where you can’t expect to bring a big heavy shop table with you everywhere you go. They are also great for shops where you are not quite sure of the layout, and want to experiment with different setups.

Portable vises work by clamping themselves to a work station. This clamp usually just looks like a big c clamp. This clamp works a lot like the vise itself in away.

Portable vises tend to be lighter, smaller, and cheaper. Making them a great option for people who are on a budget or don’t have need of a bigger vise.

These vises can also be put away when you are done with them, leaving for a tidier garage or workshop.

There are some downsides however. As I said earlier, portable vises are small and can not handle heavy workloads the way a fixed vise can. Their clamping mechanism works better on smoother surfaces, and can sometimes struggle with uneven surfaces – which can be common on the underside of drill press platforms and other machining equipment.

If you don’t get a good clamp, the vice can wiggle around while you are working with it, leading to shoddy work and potentially being a safety hazard. In a worse case scenario, the vise can drop to the floor.

Pro’s & Con’s of Portable Vises

Pros:

- Portable

- Lighter for travel

- Cheaper

- Can be put away

Cons:

- Weaker, can’t handy heavy work loads

- Can’t clamp down on all surfaces

- Risk of falling

Permanent (Fixed) Vises

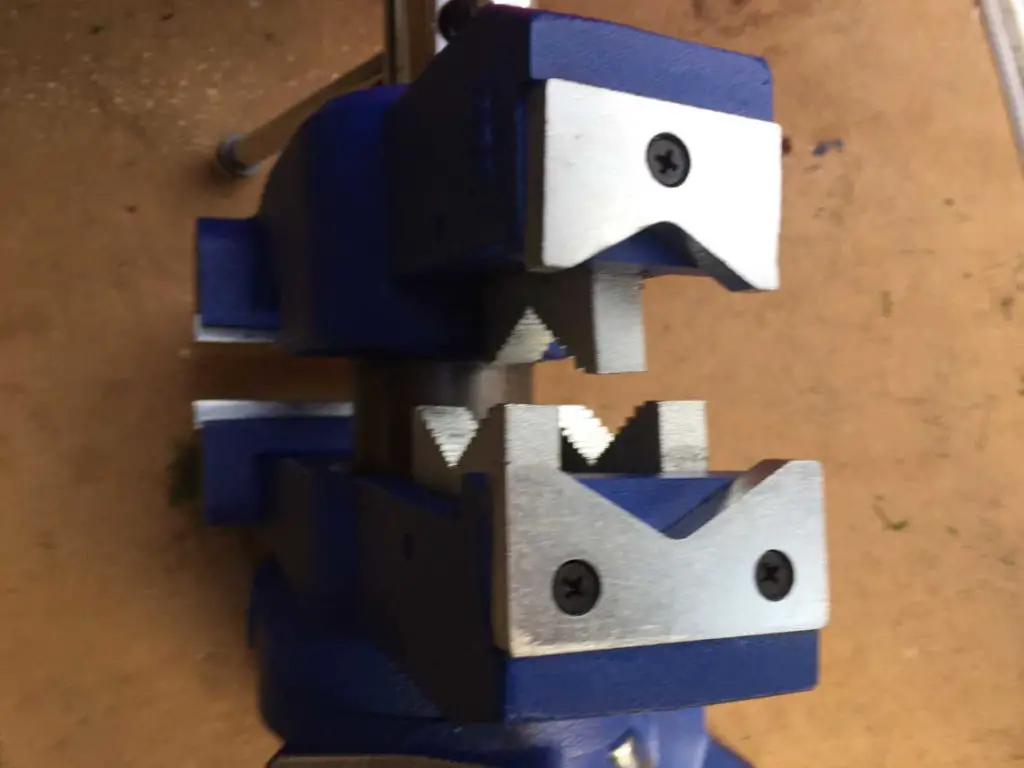

A fixed vise tends to be heavier, made of stronger material, and better for industrial workloads. Permanent vises are bolted down to work stations making them very hard to budge even when doing heavy work. Fixed vises tend to be bigger, have larger vise dimensions, and can often clamp with more force due to their larger stature.

The downside is that all this weight and strength comes at a cost. Fixed vises are expensive. They must be installed on to your workstation taking time from other tasks. They also can’t be put away when you are done with them – not easily at least.

Pro’s & Con’s of Permanent Vises

Pro’s

- Stronger – can handle heavy tasks

- Safer

- Can clamp with more force

Con’s

- Can’t be moved while bolted

- More expensive

And there you have it! Both movable and stationary vises have a place in your workshop. If you are in the market for a vise, make sure to check out my guide on the best vises.