Refractory materials are non-metallic (ceramic) materials that can withstand high temperatures. They are often used in a number of industrial applications such as furnaces, kilns, foundries incinerators, and reactors. As such, they are extremely useful to hobbyist blacksmiths and machinists who wish to build their own forge or foundry.

So which fire bricks should you buy? Well, it depends on your purpose. Not all fire bricks are designed with blacksmithing/casting in mind. Many popular fire bricks for sale at hardware stores are designed to be used for less industrial purposes such as pizza ovens. If you buy a pizza oven fire brick, it will likely deteriorate when put under the heat stress involved in forging or casting.

So what factors should you look out for? In my mind their are a couple of key factors to consider when purchasing fire bricks for a forge or foundry. They are:

- What temperature is the brick rated for?

- Do you need bricks that can reflect heat or just absorb it (insulation)?

- Will you need to cut your brick?

- Aesthetics, are you willing to sacrifice heat tolerance for the right color brick?

- Price, this one is self explanatory.

- Ph level of the forge – this one isn’t relevant to 99% of at-home hobbyists.

You will have to decide for yourself what it is you are looking for. There are lots of small trade-offs you can make when optimizing for your forge. Luckily for you, refractory materials, especially fire bricks, are not really that complicated. There are basically 2-3 types of fire bricks – more on that later.

Do I want Hard Bricks,Soft Bricks, or IFB (Insulating Fire Brick) For My Forge / Foundry?

The title pretty much says it all. In my view there are three types of fire bricks:

- Hard Fire Bricks

- Soft Fire Bricks

- Insulating Fire Bricks (IFB’s)

Pro’s and Con’s of Hard Fire Bricks

What is the difference between a hard fire brick, a soft fire brick, and an insulating firebrick (IFB)? As far as I’m aware, these terms are not standardized, and people use them in colloquial ways that make it a bit of a shit-show to try and figure out what is what. While this is a pain, there are some general rules of thumb that will allow you to quickly buy the brick you need for your project.

Hard fire bricks as the name would suggest are sturdier than the other alternatives and are often used as a structural component in many high temperature applications. While they make for a good building material in smaller forges/foundries, they do have some serious downsides.

The chief problem with hard bricks is that they are not great insulators. They take a long time to heat up, and a long time to cool down. And unlike the other alternatives, they tend to absorb the heat rather than reflect it back into the working space. This makes it harder to reach higher temperatures, and can also pose a safety risk as these bricks can get quite hot.

That being said, many forge designs utilize hard bricks extensively. For simple blacksmithing operations, hard bricks should work just fine. To prove my point, I have used a freaking campfire as a forge before…no fire bricks at all there 😉

As far as I can tell, hard fire bricks are also used for other applications such as fireplaces and pizza ovens. IF you are looking to use fire bricks for these purposes, I recommend you find a source other than this one.

I can’t really vouch for what is the best brick for those purposes, and I always get a bit skittish when it comes to food…you don’t want to be baking toxic chemicals into your home/food.

Pro’s and Con’s of Soft Fire Bricks For Forging / Casting

But if you are looking for an “optimal” forge, I think soft fire bricks are a step up in many ways. The soft variety of fire bricks are usually (again, little standardization) a better insulator than the hard fire bricks. They also tend to reflect heat back into the working space, meaning that your forge / furnace / foundry will heat up faster and cool down faster.

Soft fire bricks also tend to be rated for higher temperatures. This means they are less likely to break due to heat stress.

HOWEVER…nothing is free. Soft fire bricks as the name suggests are VERY soft. Many models of soft fire bricks can be shaped by simply scratching them with a stick. You do not want to make the bottom of your forge or foundry out of soft fire brick.

If you are constantly placing abrasive bar stock, or crucibles, or whatever on your soft fire bricks, they will get scratched up and will be in a constant need of replacement/repair.

Pro’s and Con’s of Insulating Fire Bricks (IFB’s) For Forging / Casting

While there is significant overlap between soft fire bricks and IFB’s, I find I have much better luck finding forge quality bricks when searching for IFB’s. When I look for IFB’s on the internet, I will often find bricks rated up to 2500-2800 no problem. It can be more of a hunt to find these high temp bricks when searching for soft fire bricks.

But as I said earlier, there is a lot of overlap between the two designations. IFB’s are soft fire bricks in that they have a lot of the same features. They are soft, heat reflective, and have higher temperature tolerances compared to hard bricks.

To sum up in a condensed form, each brick type has a number of different qualities:

Hard fire brick is:

- Sturdier

- Better as a structural component

- A worse insulator

- Doesn’t reflect as much heat as a soft fire brick

- Absorbs more heat – it can get hot enough on the outside to burn you

- Heats up and cools down slower

Soft fire brick is:

- Easy to work with, you can shape it with a spoon

- Lightweight

- A better insulator

- Reflects heat – meaning the inside of your forge will get hot faster

- Doesn’t absorb as much heat as the hard brick (it won’t get as hot from the outside, although it will still get very hot)

- Heats up and cools down faster

Insulating Fire Bricks (IFB’s) is:

- Higher heat tolerance bricks tend to be labeled as IFB’s

- Easy to work with, you can shape it with a spoon

- Lightweight

- A better insulator

- Reflects heat

- Doesn’t absorb as much heat as the hard brick (it won’t get as hot)

- Heats up and cools down faster

Combo Builds With Both Hard Fire Bricks And Soft Fire Bricks

Because different models of bricks have different strengths and weakness, many forge designs will utilize different brick types in the same forge. The most common example I see is that people will use IFB’s or soft bricks for the ceiling and walls of the forge, and they will use hard bricks as the “floor” of their forge. This allows you to place stock into the forge without worrying about damaging the soft bricks.

Many people will also use other refractory materials such as refractory wool or refractory paste in addition to their bricks. These materials have some serious downsides that I think don’t get discussed enough, but that is beyond the scope of this article.

I want to again stress that “soft” and “hard” are not standardized descriptions. Meaning that if you go to your local hardware store, the clerks there might not even know what they hell you are talking about. As a general rule, bricks with a higher heat tolerance will be soft bricks.

How Much Firebrick Temperature Tolerance Do I Need?

This is probably the most important question to answer when you are considering buying fire bricks. Before I begin, I want to make it explicitly clear, I’m not an expert. I’m not an engineer, I’m not a physicist, and I have never built a large scale forge or foundry. I’m just a hobbyist, so make sure to do as much research as possible when constructing your own forge. Make sure to take all the necessary safety precautions.

Now with that disqualification out of the way, let’s take a look at some common uses for fire bricks and what level of tolerance is required for that use. I have to attack this issue from this angle, as it’s impossible for me to cover every forge/furnace/foundry design ever made. Ideally you will know how hot your forge/furnace/foundry will get, but if not, we can go over some of the temperatures required for various activities.

Firebrick Temperature Tolerance For A Blacksmithing Forge

The highest temp use for a blacksmithing forge that I can think of would be forge welding solid wrought iron. This is done at a temperature range of between 2500-2700 degrees fahrenheit according to wikipedia.

This is SCREAMING hot for a blacksmithing forge. Usually blacksmiths are not working with pure wrought iron, and most steel alloys can be forge welded at a much lower temperature. This means that there is not much of a reason to run your forge this hot.

Although it’s possible to push a blacksmithing forge higher than this, a brick rated for 2500-2700 should be more than enough. You can probably get one rated for a lower temperature if you are meticulous in your heat control, but it’s good to have some margin of safety on these things. Otherwise, your forge will require constant maintenance.

And even if you are careful with your heat control, these bricks will still break down over time. Be careful to not get molten flux on your bricks, it will melt like water on a sugar cube.

Firebrick Temperature Tolerance For Casting Aluminum

According to the website engineering toolbox, aluminum melts at a temperature of 1220 degrees Fahrenheit. In the world of metals, this is an extremely low melting point. It’s not unusual for campfires to get hot enough to melt aluminum.

Which begs the question, do you need refractory brick for casting aluminum? For the odd weekend project, not really. But if you plan on doing a lot of casting, soft fire brick will allow your foundry to heat up much quicker. If you plan on doing a lot of casting, soft fire bricks will make your life significantly easier.

As with the blacksmithing forge, the temperature tolerance needed depends on how hot you run your foundry. You don’t really need a super high rated brick for casting aluminum if you keep your foundry heat low. Reflective bricks may be better for production efficiency.

Firebrick Temperature Tolerance For Casting Copper

According to the engineering toolbox site linked to above, copper melts at about 1983 degrees Fahrenheit. This is kind of a max melting point, as many copper alloys such as brass have a lower melting point.

The situation with copper is the same as all the other materials. How hot is your forge? How quickly do you need it to heat up? It makes intuitive sense that you would want to buy a brick that is rated a little hotter than what you think your forge will reach – but I can’t guarantee that this is 100% true in all cases. A brick rated for 2300 degrees ought to be enough.

Firebrick Temperature Tolerance For Casting Iron

Casting iron is significantly harder than casting many metals. Once you reach this level, casting becomes quite a bit more dangerous and difficult. As such, not many people try to cast iron or steel. Because of the danger and lack of demand, few companies sell bricks rated high enough for iron casting to the general public.

It will be hard to find bricks designed for casting iron or steel. I could not find any on amazon. If you want to find fire bricks for casting ferrous materials, I recommend 2 things:

- Know your stuff. The internet will most likely not cut it as a resource for this level of casting, you are going to have to look through textbooks that explains industry level casting. I recommend older versions of the paperback copy (to save $$$) of the book Manufacturing Engineering and Technology. This book has a lot of information that will allow you to go from small time artisan craftsman to an industrialist.

- Reach out to companies that make bricks for industry. Many will not sell small orders to consumers. That being said, it’s a numbers game. Keep reaching out and eventually you will find one that will sell to you.

Fire Bricks Safety

Fire bricks are made out of a cancerous material. Don’t work with these bricks unless you are in a highly ventilated area. It’s also a requirement to wear a high quality respirator that can filter out fine dust particles, as these refractory materials can cause silicosis and other serious health conditions. The point is, take all necessary safety precautions…don’t be a tough guy, your health is important.

Best Refractory Bricks For Sale

Shopping for specialty items like fire bricks is tricky, as such, I have tried to compile the refractory bricks (soft, hard, IFB) that are sold on amazon and are good for most projects. This is not an exhaustive list, nor does it cover every forge / foundry design. Despite this, I think these are useful products.

Best High Temp Insulating Fire Brick

One of the best selling high-temp IFB’s for sale online is the Amaco Insulating Fire Brick.

According to the manufacturer, this brick is rated up to 2600 degrees Fahrenheit. It’s very soft, and is easily shaped to whatever shape is necessary for your build. This product has many good reviews, and should be good for most projects.

Best High Temp Hard Fire Bricks For Sale

It can be hard to find hard fire bricks that have a high heat tolerance. Most hard bricks have a lower heat tolerances than the soft fire bricks. Despite this, I did manage to find one hard brick with a high heat tolerance online.

According to the manufacturer, this brick is rated up to 3000 degrees Fahrenheit, making it one of the toughest bricks (in relation to heat) in this guide.

Sadly this page is missing a fair bit of product info. If it behaves like other hard fire bricks, be careful, as these bricks will soak up the heat over time. This will lengthen the clean up time as you wait for the brick to cool down in addition to being a safety hazard.

Still, if you are looking for a brick that can withstand high heat, I don’t see too many alternatives at the moment.

Another good hard fire brick is the Rutland Products Fire Brick. This brick has a lower heat tolerance coming in at 2700 degree Fahrenheit, but it has lots of good reviews.

Another great thing about this brick in comparison to the others mentioned, is that it can be bought in packages of 6 bricks at a time. This make this brick probably the best bang for your buck brick in this guide.

Again, like all hard bricks, it’s slow to heat up and cool down. It will also retain heat for quite awhile after use, so keep that in mind.

Best Refractory Cement, Mortar, and Refractory Coating For Fire Bricks

In addition to the fire bricks themselves, there are a number of different products that can be used to enhance your forge or smeltery.

As a general rule, mortars are for binding bricks together, while cement is…cement.

Which seems straight forward, but the manufacturers of these products are a bit haphazard in their online product descriptions. It seems that most products labeled as mortars have much lower heat tolerances than those labeled as refractory cement.

It seems to me that refractory cement is used more for repairing existing structures, rather than building new ones from scratch.

I will go over a few of these products, in addition I want to mention a product called ITC-100HT. This stuff puts a reflective coating on your forge or foundry that helps reflect even more heat. It seems people often use them with refractory wool or hard bricks. I have never used it myself, but I see it often enough that I will go over one of the more popular brands on amazon.

Best Refractory Cement

This is refractory cement that according to the manufacturer, can withstand temperatures up to 3000 degrees Fahrenheit. It is stressed that this product is not for outdoor use which makes me wonder what exactly it is sensitive to when left outdoors. Is it sensitive to moisture? Sunshine? Happy little birds pooping in your forge? No one knows, it doesn’t say.

Despite their vague product descriptions, this seems to be one of the better refractory cements for sale on amazon. It is rated well, and it has many more reviews than some of the other brands.

One thing to keep in mind is that like normal concrete, this product will need to be cured. Curing is done by applying heat, but take care to cure it as slowly as you possibly can. If I recall correctly, they were at one point advertising that this cement didn’t need to be cured. I’m not sure if they are still advertising that, but I’m just telling you…heat curing seems like a wise course of action.

Because if you don’t cure it correctly, there is a good chance this stuff will bubble and crack when taking a direct blast from your forge burners – assuming you have a propane forge.

Best ITC-100HT Heat Reflection Refractory Coating

This stuff is expensive, but it works. ITC-100HT is one of the great secrets of the blacksmithing community. It allows your forge to heat up much quicker by reflecting heat. In addition, when used properly it can extend the life of your forge or foundry.

Many people have struggles with propane forges. They often can’t get them up to forge welding temperatures, or their forge is inefficient and gobbles up too much fuel. Coating the inside of a typical propane forge with ITC-100HT is often an easy fix for these problems.

Conclusion

In conclusion, forging or casting metals is an unusual hobby in that it requires immense amounts of heat. Achieving this heat in a way that is safe, fuel efficient, and quick is not easy without the help of refractory materials. These materials are lifesavers for anyone who wants to mold and shape metal.

*I talk about standards a fair bit in this article, it has been brought to my attention that the ASTM does have standards when it comes to refractory materials. If you are doing anything highly technical or unusual, I highly recommend you check those out first.

**I also want to stress that I’m not an expert on these materials. I found research for this article to be difficult as I could not find many authoritative sources online. The content of this article was written using old forum posts that I found online as sources…so take it all with a grain of salt. Stay safe y’all.

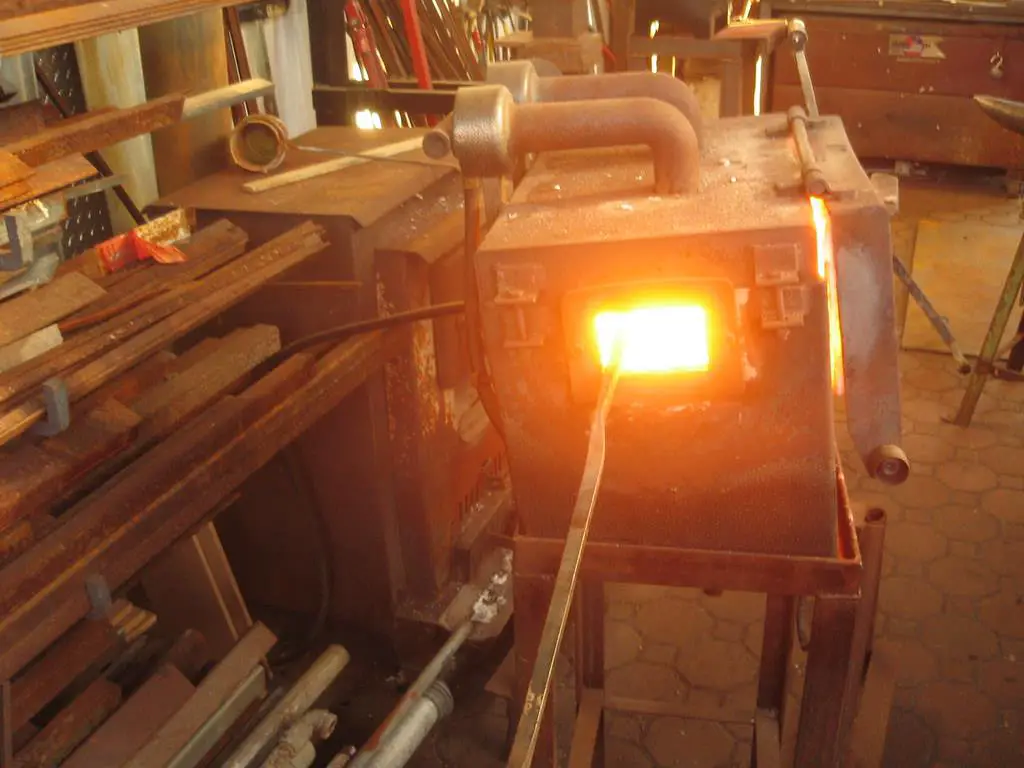

Credit for the post title image: source