With so many fuel/forge combinations, it can be hard to decide what setup to use as a beginning blacksmith. In this article I will go over 10 different fuel types, and hopefully I will be able to give you a broad overview of the different fuel types and their trade offs. With this information you will be able to answer the question: “What is the best blacksmithing fuel?”

*Note, this article takes more of an “academic” approach to analyzing forge fuels. If you are more interested in the forge itself, checkout my article on forges, which gives actionable advice that will get you forging faster.

So What Is The Best Blacksmithing Fuel?

As with most manufacturing operations, there is no best tool for every operation, there is simply the best tool for a specific job. In blacksmithing, there are many different types of projects you can make, so it’s hard for me to give you an easy one line answer that fits on a bumper sticker and tells you which fuel to use.

That being said, some quick guidelines are as follows:

- For Knife making, I like gas burners

- For Forge Welding I like Solid Fuel Forges

- For people just starting, I like solid fuel forges (usually lump charcoal), in a JABOD (just a box of dirt) forge. This makes it cheap and easy to get started.

- Aesthetically, I like solid fuel forges.

There are a million little things you can optimize for, and I can’t quickly and easily give you all the information needed so that you can make those optimizations yourself.

I have tried to organize some information that will allow you to quickly compare fuels based on the following fuel qualities:

- Max Heat Temp

- Burn Time

- Specific Energy (energy per unit of mass)

- Energy Density (energy per unit of volume)

- Smoke and Noise Pollution

The following is a list of some of the most used blacksmithing fuels:

- Soft wood

- Hardwood

- Bbq briquettes

- Lump charcoal

- Propane

- Natural gas

- Coal

- Coke

- Oil

- Electricity (induction forges)

Lets go over these fuels one by one, so that you are armed with knowledge to make decisions on the fly as you are blacksmithing.

Wood As Fuel For A Blacksmithing Forge

Some of you may be scratching your head, why did I bother to include wood fueled forges at all? While it’s true that plain old wood is pretty sub-par, you CAN use wood when forging. I always mention wood as a forge fuel source because I want to encourage newbies to use the materials they have on hand before they spend a bunch of money on a hobby they may not even end up liking.

However, there are some pretty significant drawbacks to using plain wood logs as fuel. You will struggle to get the forge hot, and you will burn through fuel very quickly. In addition, burning off logs creates a lot of messy by-product that is a pain to clean up.

It’s possible to turn some of the wood being used as fuel into charcoal through the process of pyrolysis, but this generally involves large wood piles and is difficult to do efficiently in a blacksmithing forge.

How Hot Does A Wood Blacksmithing Forge Get?

It’s possible to get a campfire hot enough (without a bellow) to make a piece of steel glow a dull cherry red. This indicates the metal is roughly 1200 degrees Fahrenheit (649 Celsius). With a bellow and some tlc, you can raise the temperature of your wood forge fire another several hundred degrees Fahrenheit.

It also depends on your forge setup. A forge built with soft refractory brick (which reflect heat), will make your forge even hotter. Not all refractory materials are the same however, check out my guide on refractory materials here.

What does this mean in practice? It means you will be nowhere near welding heat, but the stock will be hot enough that you can move some metal. Your workable heat time will be shorter, and big bends/shaping work in your stock will take longer.

What Is The Burn Time Of Wood In A Blacksmithing Forge?

There are so many variables in this question that it’s hard to answer concretely. Generally hardwoods will burn hotter and longer than softwoods. Larger logs will burn longer than smaller logs. Some logs will burn in an oxygen depleted portion of the fire and turn into semi-charcoal; this charcoal will burn much longer than the rest.

What Is The Specific Energy Of Wood in A Blacksmithing Forge?

Wikipedia states that wood has a specific energy of 16-21 MJ/kg.

While the website netrium.net states that wood has a specific energy of 15 MJ/kg.

The site FAO.ORG has an excellent table that further breaks down the specific energy of wood in terms of shaving sizes and whether or not the wood is resinous or not.

Remember, specific energy is a measurement of stored energy per unit of mass. This gives a clue of how much potential energy is stored inside a fuel source, and is useful when comparing different fuel sources.

What Is The Energy Density Of Wood In A Blacksmithing Forge?

Wikipedia states that wood has a energy density of 13 MJ/L

While netrium.net states that wood has an energy density of 9 MJ/L

I suspect this large discrepancy is due to the fact that “wood” is a rather broad category. They may have measured wood from different tree species.

Where Do I Get Wood For A Blacksmithing Forge?

Wood is generally sourced locally, and is usually not too hard to find. I would just google “Firewood + my city”. It’s also worthwhile to check craigslist, as people will often give wood away after landscaping projects. If this project took place on a farm or in a park, they will generally have A LOT of wood to give away!

Charcoal As Fuel For A Blacksmithing Forge

Not to be confused with coal, which is a different material, charcoal is the result of pyrolysis(burning) wood in low oxygen environment. Charcoal has much more carbon than normal wood (hence the black color) and is a much more efficient fuel source for a blacksmith forge.

Charcoal will burn longer and hotter than normal wood and is comparable with coal as a fuel source – more on coal later.

Charcoal was the fuel of choice for centuries of blacksmithing. It has a long and established history. Many of the world’s most famous historic blades and pieces of iron art were made with charcoal as the fuel source.

So while you will see many people online using propane or oil forges, don’t turn your nose up at charcoal. It’s cheap, and charcoal forges are easy to make which allows you to begin smithing faster.

Are There Different Types Of Charcoal?

You betcha.

Normally when people talk about charcoal for forging, they mean lump hardwood charcoal, but I will include some information on bbq briquettes as well in order to be thorough.

BBQ Briquettes As Fuel For A Blacksmith Forge

While fine for grilling, bbq briquettes are inferior for forging. They are made by pressing together wood by-products such as sawdust with anthracite coal and a bonding agent such as corn starch.

These briquettes burn up fast, and due to their composition, do not get as hot as we would like as blacksmiths. They are also dirty, they create a lot of byproduct that doesn’t get burned up. This can shorten your forges usability time and increase clean up work.

I strongly recommend lump charcoal over the bbq briquettes.

How Hot Do BBQ Briquettes get?

I’ll admit up front I have never used these as a fuel source. I would imagine that in a forge environment you would be able to heat steel up to a dull cherry red. Like the wood fuel mentioned earlier, this would put the fire at about 1200 degree Fahrenheit (549 celsius).

While this isn’t high enough for forge welds, it’s still pretty hot. This is hot enough to melt aluminum, as shown by a number of youtubers who have used charcoal as a fuel source in their aluminum casting operations.

Again, with a clever forge design, you could probably bump this temperature up even further.

Lump Charcoal As A Fuel Source For A Blacksmithing Forge

So as I mentioned earlier, lump charcoal is what people typically mean when they mention charcoal for smithing. Lump charcoal burns longer, hotter, and cleaner than wood. Charcoal has been used for centuries by smiths around the world.

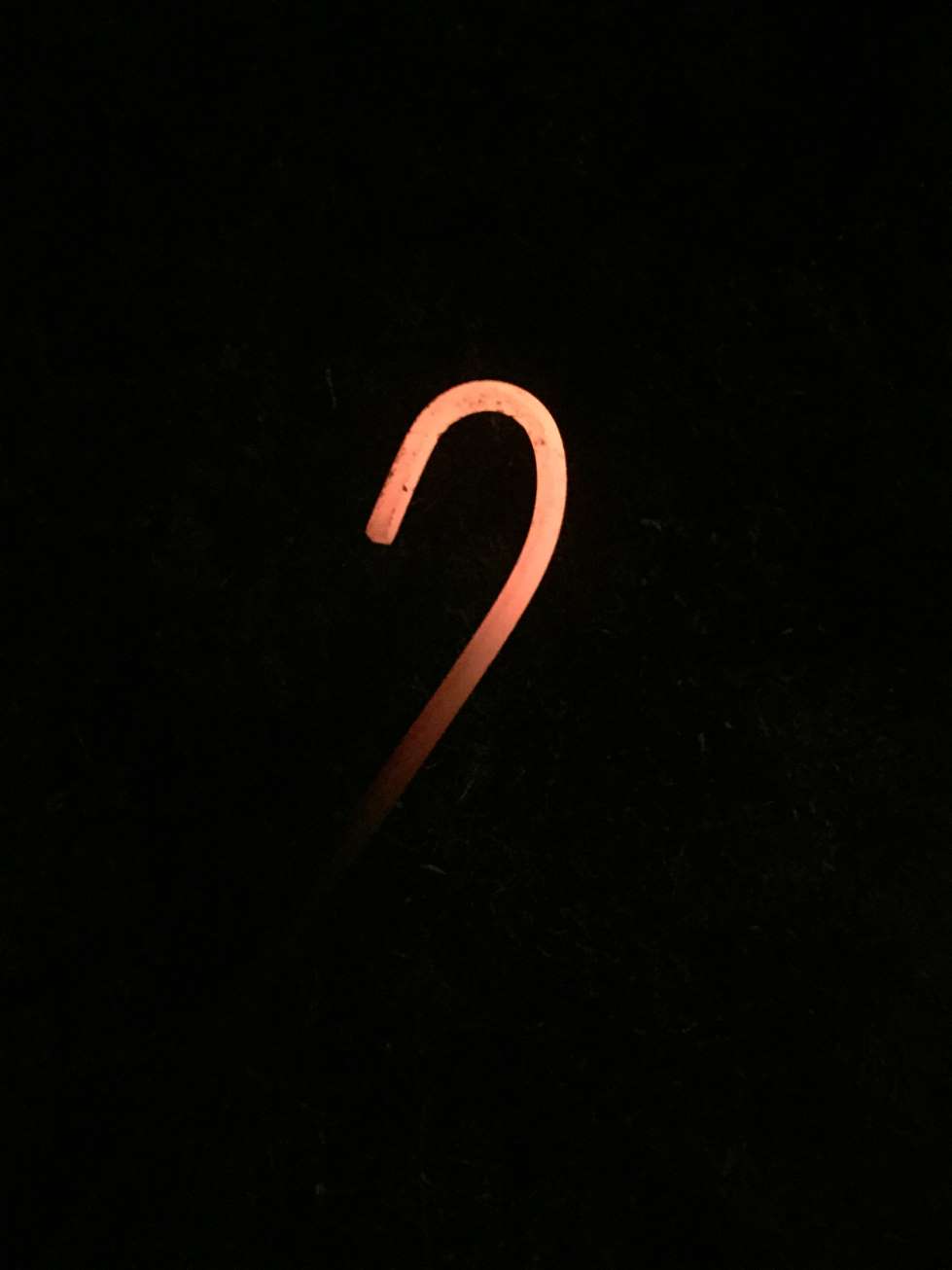

How Hot Does A Lump Charcoal Blacksmithing Forge Get?

With a bit of air you can get a lump charcoal forge hot enough for forge welding. In fact, you can make it so hot that it could melt thin pieces of metal ( such as a blade). So the simple answer is this: hot enough for blacksmithing!

A word of caution for beginners: if you have never used lump charcoal before, I should point out that it has a nasty habit of throwing out a shower of sparks when first lit. Make sure you light your forge in an appropriate area, watch out for wind, flammable objects, etc. etc.

It’s also important to keep your lump charcoal dry, as moisture contributes to the showering sparks phenomenon.

I would also encourage you not to overuse your bellow or blower when using charcoal as a fuel source. Charcoal doesn’t need as much air as coal or coke. Blasting too much air through a charcoal fire will cause you to burn through fuel unnecessarily fast.

What Is The Burn Time For A Charcoal Blacksmithing Forge?

It depends on how hot you are running your forge. At campfire temperatures, lump charcoal will burn damn near all day. At Forge temperatures, it will last for several hours again depending on how hot you run your forge.

What Is The Specific Energy For Charcoal In A Blacksmithing Forge?

Wikipedia states that charcoal has a specific energy of 30 MJ/kg. This is between 50% and 100% more energy dense by weight than plain old wood. This is great for making hotter fires that last longer. In addition, lump charcoal leaves a surprisingly small amount of ash.

What Is The Energy Density For Charcoal In A Blacksmithing Forge

*Coming Soon

Where Do I Get Charcoal For A Blacksmithing Forge?

A number of retail stores carry lump charcoal, but I hate going to the store and generally make too many shopping trips as is. I usually just buy it on amazon.

Coal As Fuel For A Blacksmithing Forge

Coal is another energy dense fuel that is used in blacksmithing. A Full run-down on coal could be an article in itself, as there is a large variety of coal types. Instead of trying to make you all coal experts, I will try to go over this class of fuels from a more generalized perspective.

What Is The Difference Between Charcoal And Coal?

Charcoal is the result of pyrolysis (burning) of wood and other organic material in a low oxygen environment.

Coal is the result of a long term geological process where organic matter (plants and animals) is buried,compressed, and heated up by the earth. Due to the number of variables involved, it’s possible to get a number of different “grades” of coal. These grades are the results of varying levels of heat, pressure, and time.

As a General rule, higher grades of coal (more carbon content) are found deeper within the earth. But as I mentioned earlier, heat and time also play a role in coal formation. Unusual thermal gradients may buck this rule.

What Are The Different Types Of Coal

What are the most common distinctions of coal? They are:

- Peat

- Lignite

- Sub-bituminous

- Bituminous

- Steam Coal

- Anthracite

- Graphite

Which Type Of Coal Is Best For A Blacksmith Forge?

While I mentioned 7 different types of coal earlier, to make things simpler I will bring this list down to just three options:

- Lignite

- Bituminous

- Anthracite

Of these three, all we be able to provide sufficient heat. Therefore, we are primarily optimizing for the materials ability to turn into coke,clinker/waste material,smoke/smell, purchasing access, and the price.

In my opinion you are best off using bituminous or anthracite. Which you should use depends on the price and your neighbors (smoke and smell). Anthracite tends to burn cleaner which is important to some of you. However, anthracite doesn’t turn into coke, and it can be hard to start and maintain the fire.

Bituminous coal is great because it is generally cheap and easy to obtain. It can be a bit smelly/smokey when it is first lit, but once the junk is burned off bituminous turns into coke quite readily.

Both coke and anthracite generally need a steady stream of air to be lit properly.

What Is Blacksmithing Coke?

Coke is coal that has been burned in a low air environment. Coke has a high carbon content and fewer impurities, making it a great fuel source – more on this later.

Some people buy premade coke when blacksmithing, and others buy bituminous coal with the intention of coking it over time. This process is described in the section below titled “Starting And Maintaining A Coal Forge.”

Just to stress this a second time, anthracite coal doesn’t coke up. This doesn’t matter though, as anthracite burns cleanly and hotly on it’s own. Anthracite and coke are fairly similar in function for blacksmithing.

The Importance Of Clinker In A Coal Forge

Earlier I mentioned clinker, so what exactly is it? Clinker is all the non combustible stuff in coal that falls to the bottom of your fire pot and gunks up your forge fire. Clinker is made up of a variety of materials such as clay, iron, sulfur, and more.

Clinker is important to blacksmiths because it can lower forge temperatures and is a PITA to constantly clean up and manage while forging.

The amount of clinker you get depends on the coal you buy and the forge you use.

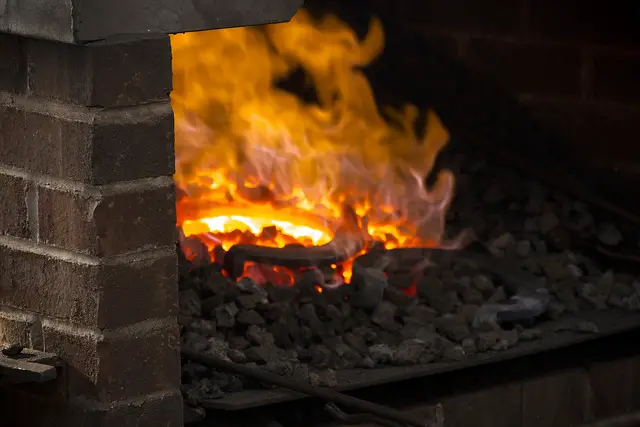

Starting And Maintaining A Coal Or Coke Forge Fire

There are a number of things that can go wrong when starting a coal fire. Bituminous coal is smokey/stinky. Anthracite and coke can be difficult to start. Below is a simple process for starting a forge fire and maintaining coke as you forge throughout the day:

- Get a steady fire going with newspaper,wood shavings, and tinder.

- Once the fire gets hot, put in the coal. If you must avoid smoke/smell, use charcoal, anthracite, or pre bought coke for this step – you can use bituminous later and more cleanly once the Fire gets going.

- Put the green bituminous coal around the outside of your fire, this allows you to burn off the smoke and smell slowly. Eventually this coal will begin to turn into coke, when that happens, you can begin to push the coke into the heart of the fire.

- Rinse and repeat until done. When you are finished with your forge, you can use the leftover coke from this process to cleanly begin your next forging session.

How Hot Does A Coal Forge Get?

Both bituminous coal and anthracite coal will get you to welding temperatures if properly maintained. This means periodically removing clinker and ensuring adequate air flow.

What Is The Burn Time Of Coal In A Blacksmithing Forge?

-

- This depends on:

- The quality/grade of coal being used.

- The amount of airflow you provide the fire.

- The size of your coal mound.

- The skill with which you manage your fire.

Due to the number of variables involved, it’s hard for me to be more specific. The best way to figure out your coal consumption is to simply begin smithing :).

What Is The Specific Energy Of Coal in A Blacksmithing Forge?

According to The Balance, coal has the following specific energies in MJ/kg:

- Lignite: 5.5-14.3 MJ/kg

- Sub-Bituminous: 8.3-25 MJ/kg

- Bituminous: 18.8-29.3 MJ/kg

- Anthracite: 30 MJ/kg

However, you can get much more detailed than this. Another Site breaks down coal into 13 subcategories and provides specific energies for each of them. If you are into this kind of stuff I highly recommend you check it out!

As you can see there is incredibly variability in all fuels sources. Still, the main point is that coal is fairly energy dense and is perfect for the purpose of blacksmithing.

What Is The Energy Density Of Coal In A Blacksmithing Forge?

*Coming Soon

Coal Size For A Blacksmithing Forge

Coal comes in a variety of different sizes, from big to small they are:

- Stove 2- 7/16 X 1-⅝ inches

- Nut 1-⅝ X 13/16 inches

- Pea 13/16 X 9/16 inches

- Buckwheat #1 9/16 X 5/16 inches

- Rice 5/16 X 3/16 inches

- Barley 3/16 X 3/32 inches

- Buckwheat #4 3/32 X 3/64 inches

- Buckwheat #5 3/64 X 0 inches

The information from this list comes from the Hackman, Williams & Company Website

What Is The Best Coal Size For Blacksmithing?

Most smiths I know burn nut or pea sized coal. Larger coal sizes tend to let more air through when burning, this makes for a more intense fire with a shorter burn time. This makes nut and pea sized coal perfect for blacksmithing. Conveniently enough, these sizes tend to be a bit easier to find and purchase.

You may be tempted to try smaller coal sizes for long forging sessions, but I wouldn’t recommend it. Smaller coal sizes can trap gas under your forge fire causing nasty flare ups when forging.

Where Do I Get Coal For A Blacksmithing Forge?

You can buy a small 25lb bag bituminous coal on amazon. You can also buy it in bulk.

If you are looking for the generally cleaner anthracite, that can also be bought online in the following sizes:

- Stove (Biggest) – *edit* you used to be able to buy this but the seller took their product down

- Nut – Ideal size IMO

- Rice – Too small IMO

Coke As Fuel For A Blacksmithing Forge

As mentioned earlier in this article, coke is the result of bituminous charcoal burning in a low air environment. It has properties similar to anthracite, in that it burns cleanly and at a high temperature. Many smiths use coke, or they try to tend to their coal forge in such a way as to produce coke.

Coke has been used for centuries, and in some parts of the world, for millennia. Coke has been used for blacksmithing, blast furnaces, and many other industrial processes. Coke was one of the primary energy sources that drove the industrial revolution.

For our purposes, it is yet another legitimate solid fuel source for blacksmithing, and works just as well as charcoal or coal.

How Hot Does A Coke Forge Get?

Coke fueled blacksmithing forges can get hot enough for forge welding. In fact, it can get much hotter than that, as coke was used as a fuel source for steel casting for centuries. This stuff can get as hot as you want – practically speaking of course.

What Is The Burn Time Of Coke In A Blacksmithing Forge?

As with our other solid fuel sources, this largely comes down to:

- Air flow

- Forge design

- Intended purpose

The hotter you burn it, the shorter the burn time.

What Is The Specific Energy Of Coke in A Blacksmithing Forge?

The website FAO.org gives coke a 28.4 MJ/kg

The site Engineering Toolbox provides the figure of 26 MJ/kg for coke.

ਭ This makes coke more energy dense per unit of mass than bituminous coal.

ਭ This makes coke LESS energy dense per unit of mass than anthracite coal.

What Is The Energy Density Of Coke In A Blacksmithing Forge?

*Coming Soon

Propane As Fuel For A Blacksmithing Forge

Propane is the first fuel that we are analyzing that will have a noticeably different set of advantages and disadvantages.

For starters, unlike the solid fuels we have discussed previously, propane is clean. Burning propane does not leave all the nasty residue that solid fuel forges do. Propane makes much less smoke, and has quicker setup and cleanup time. Propane is also incredibly energy dense, and can heat up a piece of stock in a very short amount of time.

Other advantages of propane fueled forges include temperature control and the ability to heat multiple pieces at once.

After a bit of tinkering in the initial setup, it becomes much easier to control temperature with propane forges compared to solid fuel forges.

The ability to heat multiple pieces at once is also a huge benefit. With the temperature control of gas forges, you don’t have to worry about one piece getting too hot and melting while the other struggles to get heat. You don’t have to worry about smothering the fire with too much stock when using gas fueled forges.

A final benefit to propane forges is that it is incredibly easy to get more fuel. Buying propane is as simple as going to the local hardware store and exchanging your empty tank for a full one.

To summarize the advantages:

- Clean

- Quick setup

- Quick cleanup

- Energy dense

- Temperature control

- Easier to work with multiple pieces at once

- Heats up quickly

- It’s easy to find propane fuel

But it does have some downsides. Some propane forges can be quite noisy – although to be fair, so is blacksmithing! And while propane forges can be quickly set up,used,cleaned, and then put away, they can be a bit tricky to build initially.

There are more parts than can go wrong in a gas forge compared to a solid fuel forge. There is a lot of danger in building a bad forge. If propane doesn’t flow through your pipes properly, you can get a buildup of gas that will make a spectacular boom.

You also have to really watch out for galvanized parts, galvanized pipes as a general rule are no bueno when blacksmithing.

If you hurt yourself with a bad build you are not just harming yourself, but also making life more difficult for other local blacksmiths, as they will be viewed with more suspicion. So make sure to do your homework and build a proper and safe propane forge.

Another con for propane forges is that they tend to be less flexible with unusually shaped projects or large objects. This is because the heart of a propane forge must be a “closed’ environment in order to retain the heat thrown off by the torch.

This often results in a cramped forge opening or mouth that can limit the types of objects that will fit inside the forge.

Another con to propane forges is that many designs rely on refractory wool and refractory cement. These materials are flexible and easy to shape, but they tend to break down over time. Propane forges require a bit more maintenance than solid fuel forges.

Speaking of these materials, a good propane forge will run hotter than the temperature tolerances of cheaper refractory materials. So make sure to pay close attention to these tolerances, otherwise you will destroy your forge in a short period of time.

To summarize the cons:

- Noise

- More dangerous when built improperly

- Don’t work well with large or unusual projects

- Require more forge repair maintenance than solid fuel forges

I don’t mean to point out the cons to scare you away. Many smiths use and absolutely love their propane forges!

How Hot Does A Propane Forge Get?

A good propane forge can get to forge welding temperatures. But like all things, the devil is in the details. It’s fairly easy to build an inefficient gas forge. If I had to hazard a guess, I would say most propane forges run from 2300-2400 degrees Fahrenheit (1260 Celsius – 1315 Celsius).

To repeat from earlier, running a propane forge too hot will cause your forge to break down faster. Propane forges tend to rely on refractory wool and some sort of refractory coating. These materials tend to break down over time, and will lead to more maintenance.

How Long Does A 20 Pound Propane Tank Last In A Blacksmithing Forge?

Depends on your forge setup. For a ballpark figure I would say about 15 hours.

What Is The Specific Energy Of Propane in A Blacksmithing Forge?

According to a pdf from Dartmouth liquefied propane has a specific energy of 46 MJ/kg

What Is The Energy Density Of Propane In A Blacksmithing Forge?

According to from engineering toolbox liquefied propane has a specific energy of 25.1 MJ/L

What Is The Price Of Propane For A Blacksmithing Forge?

Again depends on a number of variables. For a ballpark estimate I would guess about 1$ per pound for tank exchanges.

Natural Gas (Methane) As Fuel For A Blacksmithing Forge

Forges that utilizes natural gas (Methane) for fuel are uncommon but not unheard of. Generally these types of forges are used by people that are already hooked up to natural gas in some capacity. Sadly I’m of little use when it comes to natural gas as a forge fuel source… so I recommend you look at the following thread on IforgeIron

What Is The Specific Energy Of Natural Gas in A Blacksmithing Forge?

55.4 MJ/kg according to A pdf by dartmouth

What Is The Energy Density Of Natural Gas In A Blacksmithing Forge?

*Coming Soon

Oil As Fuel For A Blacksmithing Forge

*Coming Soon, these are not as common so you are not missing anything essential.

Electricity As Fuel For A Blacksmithing Forge

*Coming Soon, these are not as common so you are not missing anything essential.

How Do I Put Out My Forge Fire?

With solid fuels, I usually begin by stopping all air flow to the forge. After that, I push all the fuel away from the central heat of the fire. I then sprinkle a little bit of water on the fuel that I separated and pushed away.

Don’t pour the water, and don’t pour water into the center of your forge pot.

Watch out for the steam, it’s very hot.

The water can crack the forge if you are not careful.

You can also always scoop the fuel out and put it into a bucket of water if you need to be 100% sure your forge is out.

With the fresh fuel out of the way, and airflow turned off, the fire in the middle will usually quickly go out. This is especially true for coke and anthracite coal.

* A quick note, this article is still currently under construction. It currently doesn’t have enough images, is full of egregious English errors, and may not make sense in all spots. For personal reasons I have decided to publish it early, but I will make a second pass over it soon, hopefully cleaning up any issues within. I apologize in advance for any inconvenience this may cause.