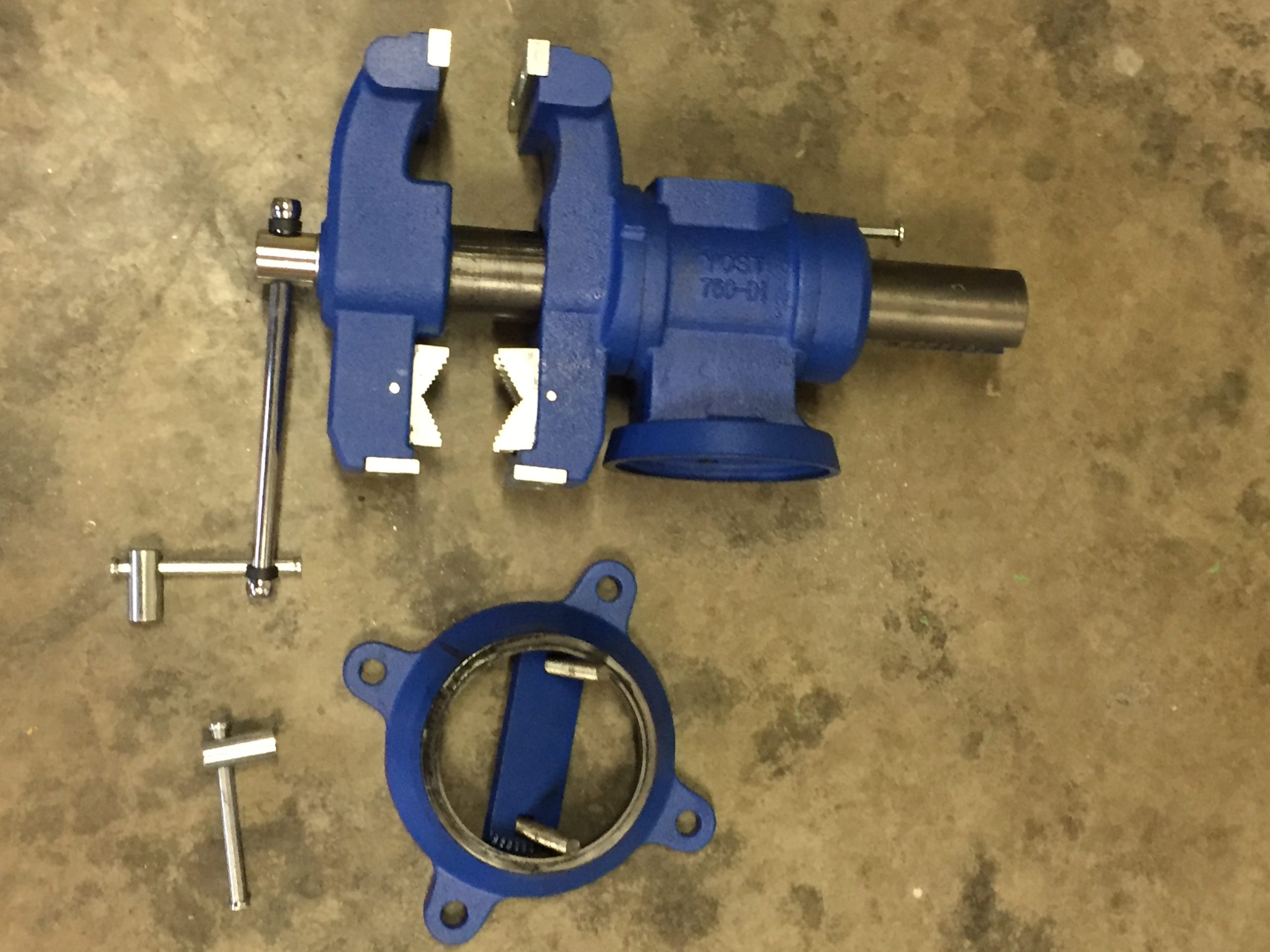

What are vises (sometimes spelled vices) made of? Vises are made from some combination of cast iron and steel. The main body is usually made from either cast ductile iron or gray iron. The vise jaws, handle, and lead screw are often made of steel.

There are a million different models of vises out there, so this article will stick to explaining general rules about vises rather than absolute rules.

What is the main body of a vise made of?

As I said earlier, the main body of a vise is usually made out of cast iron, but cast iron is not a very specific term. Cast iron refers to a family of iron based alloys composed of iron, carbon (between 2%-4.5%), and silicon (up to 3.5%). These elements are not arbitrary. Cast irons forms graphite flakes (carbon) in the metal while casting, and silicon is a powerful graphitizer, meaning it controls how those graphite flakes are formed. In general, less silicon is used for high carbon iron, and more silicon is used for low carbon iron. I will go into more detail as to why these graphite flakes are important later on.

Cast irons are classified according to their solidification morphology from the eutectic temperature (definition source) These classifications are as follows:

- gray cast iron or gray iron

- Ductile cast iron, nodular cast iron, or spheroidal graphite cast iron

- white cast iron

- malleable iron

- compacted graphite iron

In addition, cast irons are also classified by their structure:

- ferritic

- pearlitic

- quenched and tempered

- austempered

I’m not going to fully explain the definitions above, as it would take two pages. I’m also not going to focus on the structure, as it isn’t usually advertised when you are purchasing a vise. I just wanted to give you a glimpse of how deep the rabbit hole goes if you are interested in this sort of thing.

I will focus on the gray iron classification and the ductile cast iron classification, as these are the most relevant to the evaluation of vises.

Gray Iron Properties

Gray iron has large graphite flakes within it’s structure. These graphite flakes greatly affect the material properties of gray iron. Gray iron has minimal ductility and is very brittle. It is strong in compression but weak in tension. The presence of graphite flakes in gray iron gives it a dampening property that allows gray iron to dissipate energy better than most materials. This is why gray iron is often used a base of machines and mechanical structures.

Fun side note – this dampening property plays a big role in the analysis of anvils in blacksmithing – which is my professional background. You will often find smiths tapping anvils to listen to the sound, If it’s a loud, bright ringing sound, the anvil face is made of steel. If the anvil makes a dull thud, it’s made of cast iron! It is the dampening property of the graphite flakes in gray cast iron that makes this dull thud sound.

Other Properties of gray iron include:

- Excellent machinability

- Excellent wear resistance

- Good corrosion resistance

Gray Iron And Vises

Now for the part you care about: how does a gray iron vise compare to vises made of other materials? In short: gray iron vises are quiet, hard, and cheap. The downside is they are brittle, but for the cast majority of vise work this won’t be a problem. A gray iron vise will work well!

Ductile Iron

In ductile iron, the graphite within the metal comes in evenly spaced out nodules (sphere) rather than flakes. Ductile iron is made by a small addition of magnesium to the iron during production. This allows the iron to be more ductile and shock resistant than gray iron, but at the expense of hardness.

Ductile iron is seen as a material that is somewhere between gray cast iron and steel in terms of it’s material properties. Like gray cast iron, ductile iron has a much lower melting point than steel – making the production process much simpler and cheaper. In terms of machinability, wear resistance, high strength, toughness, ductility, hot workability,weldabilty, and hardenability, ductile iron is more like steel than gray iron.

Ductile Iron and Vises

Vises made out of ductile iron are less brittle and more resistant to shock blows than vises made out of gray cast iron. They are less hard and more susceptible to scratches than gray iron. Both will work fine for 99% of vise tasks, but I believe ductile iron vises are superior to gray cast iron vises.

Steel Bodied Vises

I’ll be a little more brief here as these are less common than vises with cast iron bodies. There are many steel alloys, and many heat treatments than can be applied to higher carbon steels. This makes generalizations difficult. That being said: Steel is less brittle and less hard than cast iron. It makes up for this by being much tougher – meaning it can absorb shock blows without failure. Unlike cast iron, steel has excellent tensile strength. Steel is also more malleable, meaning it will permanently deform when struck, rather than crack or break.

In short: A steel bodied vise can withstand a lot more abuse than a cast iron body vise can. If you plan on really clamping your vise tight, or doing vigorous hammering, bending, or cutting on your vise, a steel bodied vise may be worth the extra money it will cost. Steel bodied vises do not dampen energy as well as cast iron vises, so your work may be noisier if that’s of concern to you.

Aluminum Vise Bodies

In the name of thoroughness I thought it might be worth mentioning that you can find smaller vises made out of aluminum…In my opinion you should not even bother with these, they are too flimsy.

Material composition of vise lead screws, handles, and jaws

All of the above will likely be made out of steel. You may come across handles and jaws that are made with softer/cheaper materials. The lead screw will almost always be made out of a hardened (heat treated) high carbon steel.

High carbon steel is ideal for this role, as the screw must be hard enough to resist wear and tear through use, but it must not be so brittle that it will completely snap under high clamping loads. Low carbon steels are too soft and will need constant repairing under heavy repeated use. It’s also impossible to heat treat VERY low carbon steels, and difficult to heat treat moderately low carbon steels, so heat treatment doesn’t solve the problem.

Important note: The weakest point in a vise is usually the lead screw, base plate, or inner base plate on swivel vises. In my experience these are usually the first parts to break in a vise.

Vise steel finish

Finally, the vast majority of vises will come with some sort of finish. These finishes apply a bit of decoration and make the vise more resistant to corrosion. This finish can be applied either as a liquid paint or as a powder coating.

Summary

The vast majority of people do not need to optimize for vise material composition. If you are not the vast majority of people, than you have to choose between cast gray iron, cast ductile iron, and steel vises. Gray cast iron is cheap, dampens sound, and is very durable at the expense of being brittle and prone to fractures when subjected to shock blows.

Ductile iron is a great choice of material, as it is still fairly cheap, and is more resistant to shock blows and rough use than a cast iron vise is.

A steel vise is noisy, but will be able to handle rough workloads. Per lb it may be more expensive, but there are a lot of variables at play when determining price. Steel vises can be very sturdy if well built.

I recommend vises of all materials in my guide to the best 3 bench vises.